BUSINESS LINE

Business Area

High Vacuum

Brazing Technology

Manufacturing process of CNTs field-emission ultra violet CL light-emitting vacuum sealed light source

- Development of vacuum brazing bonding technology

for four types of materials - Optimization of filler process optimized for high and

low temperatures with eco-friendly filler composition - Optimization of anode window material, thickness, surface

enhancement control and aluminum metal reflection film coating

for UV-C Sterilization light transmittance improvement - Production of more than 30 light sources per batch

* 4 types of materials : alumina, Oxygen-free copper, Kovar, Sapphire

Need for state-of-the- art complex high vacuum brazing technology

Low-temperature bonding area below 400 ℃ (final vacuum sealed)

High temperature brazing area above 800℃

High-performance

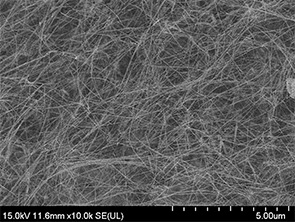

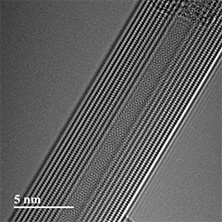

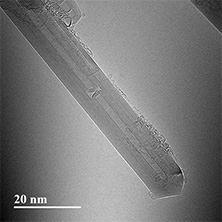

CNT synthesis

Manufacturing technology

World-leading nanomaterial manufacturing

High-performance electron

emission source

manufacturing technology

Possession of manufacturing process technology for

CNT electron emission source cathode

Self-manufactured high-performance CNT material

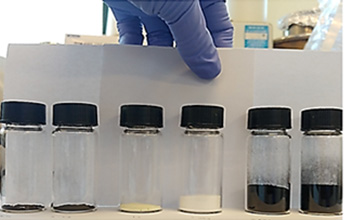

High-performance CNT paste manufacturing